Industrial Mats

Spilled liquids can cause a lot of havoc. That's true for all liquids, even such otherwise harmless ones as water because even water can pose a slip and fall hazard. But you can easily prevent problems -- read on for some ways to use industrial mats. Industrial Mats are a whole different category than those that you may buy at a big box store or even at the hardware store. They're much sturdier, more heavy duty, and built to cope with much greater amounts of liquids. They can also handle a greater range of liquids. Besides, there are different types, depending on what spills are likely to happen where you plan to place your mats. The basic industrial absorbent floor mat It's usually made out of recycled polypropylene and acrylic fibers. And it's tough and an excellent all-around mat for your facility. It will stand up to any amount of foot traffic, and it will absorb any and all liquids, including coolants, solvents, oils. They're great to use under machinery and in walkways to keep them safe for your employees, your visitors, and yourself.

Rail road track mat

Next, there's a curious mat called "rail road track mat." It is specifically manufactured for use on rail road tracks -- to protect the environment from spills, which accounts for the name. And there are two kinds: 59" rolls that will fit between the rails, and also rolls that are 19" wide that you can place along the outside of the rails. Railroad mats are extremely durable -- made out of layers of melt blown absorbent material, plus a top layer that consists of needle-punched felt. In addition, there's a ground layer, which has a backing of a chemical-resistant material.

The forklift mat

There are other mats as well, and the sturdiest of them all Industrial Floor Mats is the forklift mat. Imagine how heavy a forklift is -- and the forklift mat is placed underneath it and has to withstand the forklift driving over it. You can just park your forklift on those mats and they will absorb any leaking fluids, from oils to battery acid. Forklift mats have a non-penetrable backing to ensure that any fluid that drips on them does not seep through and get onto the ground underneath.

Liquids leak and drip and over spray from production equipment lands on the floors and walkways. Employees use these areas but in some retail areas customers are also at risk for a slip and fall accident.

1) Use Absorbent universal socks are the best choice for industrial applications. The general purpose absorbent socks absorb both oil and water base liquids and drips. The socks can be molded around leaky equipment, machinery and drums to stop spill before these spills reach walkways and present an immediate hazard.

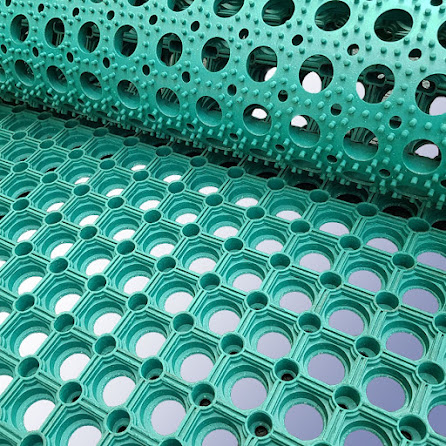

2) Use slip resistant industrial matting in areas where a smooth floor presents a hazard. Provide safe footing in work areas use matting that grips the floor for safe walking.

Absorbent industrial matting provides good protection by drawing and trapping liquids into the inner highly absorbent melt blown layer. Work areas can be lined with absorbent mats to keep them dry, comfortable and non-slip.

3) Make good housekeeping a priority. Cut liability exposure to slip and falls. Eliminates possible EPA fines for polluting if improper cleaning techniques are being used. You improve the appearance of your facility by eliminating unsightly oil spills. The first step in keeping work areas safe is keeping them free of liquid spills and hazards.

Comments

Post a Comment