What are Workshop Mats?

Briefly put, a Workshop Mats is a term to describe any type of matting designed to be in a workshop environment. This can be anywhere from a hobbyist’s own woodworking area to automotive garages, welding bays and large-scale manufacturing plants. The diversity between workshops and the type of work conducted within them means that many workshops will have at least two or more different types of workshop matting, with each being designed for a specific purpose.

What are the Advantages of using Workshop Mats?

Industrial workshop mats help to protect both floors and workers, by providing a tough but comfortable surface for them to stand on. The mats help to absorb impacts from heavy tools and equipment and prevent the spread of machining oils and swarf to other parts of the building. Many of them also have excellent anti-fatigue properties, guaranteeing that employees get the best possible working environment while also complying with necessary health & safety rules and regulations.

The main features and functionalities of industrial workshop mats include:

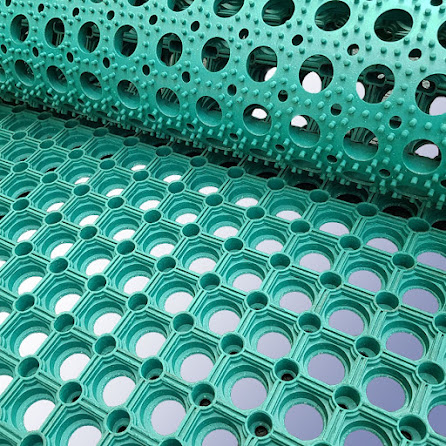

Trapping Machine Oils and Swarf – Swarf such as metal fillings, wood shavings and other particles can cause major health and hygiene risks if left unattended. For these environments, we stock workshop mats with an array of compact holes, indents or small wells to collect and trap any swarf when working.

Slip Resistance – Anti-Slip Mats prevent or greatly reduce the risk of workers slipping, tripping or falling within the surrounding area. These slip-resistant mats are usually made from rubber, which helps to keep the mat fixed into position on the floor.

Wear Resistance - In factories, garages and workshops with high volumes of foot and operational vehicle traffic, it is imperative that the mats are durable to sustain the pressure, weight and materials they come in contact which throughout the day.

Oil Resistance – Oil Resistance is especially important in factories, manufacturing plants, garages that handle any fuel or oily-based products.

Static Resistance - Anti-Static Mats are mats that stop ESD (electrostatic discharge) when in contact with electrical components. ESD is very problematic due to how it can not only damage and destroy any components during operations but can also deal fatal electrical shocks if not dealt with correctly. This is where Anti-Static Mats, sometimes called Grounding or ESD Mats, come into play.

Fire Resistance – For welders, fire resistance is critical due to hot sparks, liquids and other substances that fall on the floor. All our mats with fire resistance have all passed a Flame Retardancy Certificate - a series of tests conducted by a third-party invigilator testing how well a sample of the mat performs in hot and flammable environments.

Types of Industrial Workshop Mats

Anti-slip mats

As reported by the Health and Safety Executive, 29% of workers were injured by a slip, trip or fall between 2016 and 2017 while in work. To prevent this, more and more companies are opting for anti-slip flooring solutions in and around work stations, corridors and loading bays. Slip resistance is not only the main feature for some mats but also a mandatory requirement for professionals dealing with oil and fuel-based products thought their work.

Anti-fatigue mats

Anti-Fatigue Mats reduce the symptoms of fatigue caused by standing for long periods of time. Studies have proven that using Anti-Fatigue Mats in the workplace will make employees more comfortable, increasing productivity, reduce work-related injuries and boost morale and are very popular within production plants, factories and distribution centers.

Swarf mats

Swarf mats help to maintain health and safety and by helping to collect and isolate small pieces of debris, or “swarf”, that are produced by machining or other industrial processes. This type of matting is popular in workshops where metals and wood are machined into products, as well as in commercial kitchens and food production facilities where produce is prone to falling on the floor.

Comments

Post a Comment